Description

TPE or TPV

General Information

Let’s see what TPE or TPV is. Polyolefin thermoplastic elastomers include thermoplastic vulcanizate (TPV), also called elastomeric alloy (EA). Typically, TPVs comprise a polyolefin (such as polypropylene or polyethylene) and an elastomer (SBR, NR, EPDM, NBR, or Butyl). The ratio of hard to soft segments varies greatly between species. The majority of TPVs are rubber mixtures made from PP and EPDM. Chemical reactions are used to create TPV. Completely cured elastomer particles (cross linked elastomer particles on the micron scale) are uniformly dispersed in a polyolefin matrix during the dynamic vulcanization stage of TPV manufacture. As a result, TPV compounds can be processed similarly to rubber but with the benefit of being thermoplastic. Unlike elastomers, TPV products do not require vulcanization in the processing stage. This considerably simplifies the downstream processing operation and shortens the cycle durations. The parts don’t need to be annealed or deburred in further processing, unlike elastomer processing, which is a bonus.

If thermoplastic elastomer hybrids cannot adhere cohesively, they can be attached mechanically using multi-component injection molding. There’s also the bonus that TEH chemicals can be recycled. Sprues and start-up materials can be mixed in with virgin stuff up to a specific amount.

Usage of TPE or TPV

The automotive sector primarily uses TPE or TPV, specifically for CVJ boots and airbag covers. Its melt-flowing properties also find application in construction, where it is utilized for things like glazing seals and weather strips.

| Applications |

| Weather stripping and seals

Commercial glazing gaskets Expansion joints and gaskets Housewares Power tools Electrical wire and cable Automotive parts |

TPE or TPV

Technical data sheet & Chemical Formula

TPE or TPV are thermoplastic elastomers typically made from polypropylene and ethylene propylene diene monomer (EPDM) rubber. The vulcanized EPDM rubber within the polypropylene matrix provides good compression set resistance. TPVs offer various benefits, including aging performance, chemical resistance, and elastomeric qualities like compression and tension sets. C27H36N10 is its chemical formula.

| Physical | Nominal Value | Unit |

| Specific Gravity | ||

| — | 0.929 to 0.947 | |

| 73°F | 0.927 to 0.944 | g/cm³ |

| Melt Mass-Flow Rate (MFR) (190°C/2.16 kg) | 1.9 to 9.2 | g/10 min |

| Mechanical | Nominal Value | Unit |

| Shear Strength (73°F) | 1080 to 2660 | psi |

| Peak Melting Temperature | 194 to 208 | °F |

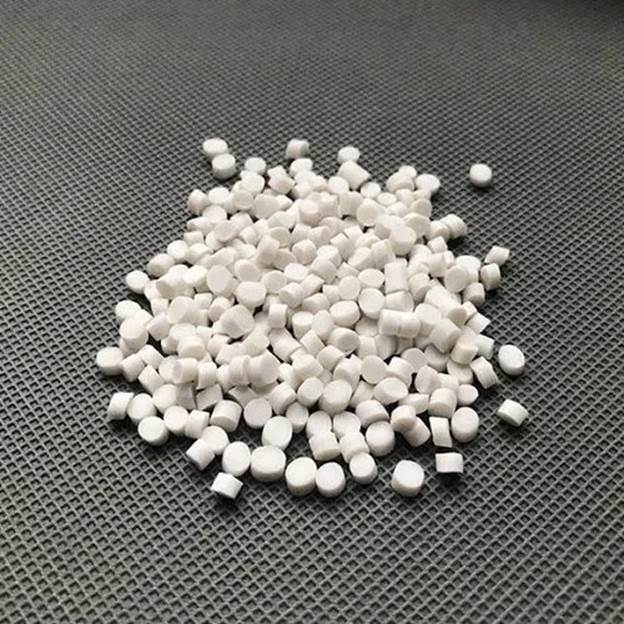

Packing of TPE or TPV

Packing

TPE or TPV is usually packed in 25 to 500 kg PP bags.

Safety & warning & transportation of TPE or TPV

Currently, no laws in place classify TPE or TPV as a threat to human or environmental health. It is anticipated that the product will not pose any environmental risks. Bring yourself outside to get some fresh air; if your condition does not improve, you should seek medical attention. If you believe you require medical attention, you should contact someone immediately. Do not apply ice to the molten substance that is on the skin; rather, cool off by standing underneath a stream that is moving quickly. Showering is NOT a method that can be used to eliminate the chemical. When the tissue is removed, it may cause severe trauma to the tissues that surround it. Do not put off receiving medical assistance; do it immediately. Always maintain ready access to a secure and well-stocked emergency shower. It might be helpful to give your eyes some TLC by splashing some water in them for four or five seconds every once in a while.

Do not put your contacts back in your eyes, and stop flushing after the first minute has passed. If you continue to experience these issues, you should consult a physician, preferably an ophthalmologist. If it is swallowed, seek immediate medical attention. The possibility of having constipation. In addition, no specific procedures for its handling are required when it is being transported.

Reviews

There are no reviews yet.