Description

General information about HDPE injection

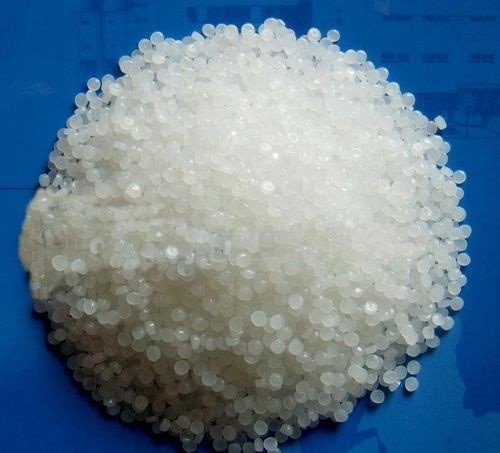

High-density polyethylene injection or in other words HDPE injection is a type of thermoplastic that has a linear structure. This product is an economic thermoplastic that is produced at special temperatures and pressure. This issue has made this product have unique features and suitable for use in various fields. High-density polyethylene injection is a flexible product and has a transparent and waxy state. In addition, this product is resistant to weather factors as well as very low temperatures. HDPE injection is very resistant to many chemical and industrial solvents, and this is why it is used for packaging these materials. In addition, this product is insulated against electricity and has a very good resistance against moisture. This type of polyethylene has high tensile strength compared to other forms of polyethylene.

Usage of HDPE injection

HDPE injection is used in various fields. The main uses of this product include making packaging such as boxes, bottles, plastic lids, etc. In addition, this material is also used to make many household appliances because it has good strength. Another field of high-density polyethylene injection consumption is the fiber and textile industry. Due to the high tensile strength of injected polyethylene, this product can be used to make rope, agricultural nets, fishing nets, and … . HDPE injection is a suitable material for making various pipes and fittings because it is very resistant to chemical factors and does not get damaged easily. In general, we have a direct and indirect need for this chemical in our daily life, and we cannot live without it. In some cases, the containers and tools we use are directly produced from this chemical. On the other hand, many of the devices that are currently used may have important parts inside them that are made of high-density polyethylene injection.

| Packing industries | making packaging such as boxes, bottles, plastic lids, etc |

| Consumer industries | household appliances, fiber and textile industry, pipes |

| Greenhouse and agriculture | rope, agricultural nets, fishing nets |

Technical data sheet & chemical Formula

The chemical formula of HDPE injection is not different from the chemical formula of heavy polyethylene and it is displayed as (C2H4)n. It is good to know that this material is used for injection molding. In general, polyethylene’s products are classified into two different categories: hard and flexible. High-density polyethylene injection is one of the hard types of polyethylene that is so resistant. The higher the density of polyethylene, the stronger and more resistant the product will be. This issue has made this product known as an excellent option for various uses.

| chemical formula | (C2H4)n |

| Chemical Family | Polyolefin |

| Color | Translucent to White |

| Danger of explosion | Product is not explosive |

| Melting point | 120-150°C |

| Form | Solid |

How is packing of HDPE injection?

HDPE injection packaging usually varies according to the diagnosis of the manufacturing company. Usually, for production purposes, the packages of this product enter the market as 25 kg. These packages are usually in the form of plastic bags to prevent environmental factors such as moisture to damage high-density polyethylene Injection. Of course, in general, high-density polyethylene injection is a very resistant material. However, the introduction of some environmental factors can slightly overshadow the quality of this product.

Safety & warning & transportation

HDPE injection is one of the crude oil products. Crude oil is a highly flammable product and this has caused the products produced from this product to be also flammable. In general, high-density polyethylene injection is not a flammable product by itself, but it may not be very resistant to heat in some cases. So, it is better that you pay attention to various factors to store this product. In addition to this, high-density polyethylene Injection is not very resistant to ultraviolet rays, so it is better to place this product in an environment where this radiation exists. If you want to store high-density polyethylene Injection, make sure to try to store this product in a dark, relatively cool, clean, and dry environment so that you don’t have any problems.

Reviews

There are no reviews yet.