Description

General information about LLDPE Injection

Liner Low-Density Polyethylene Injection, or LLDPE Injection, is one of the types of flexible thermoplastics, which is used for the production of various products due to its adaptability. As its name suggests, this product has very little weight, but it has very good resistance. This product does not break easily against impact and maintains its useful properties due to proper flexibility. In addition to these, Liner Low-Density Polyethylene Injection has very high chemical resistance and chemicals cannot easily affect the quality of this product. LLDPE Injection has high tensile strength, and for this reason, the products produced from Liner Low-Density Polyethylene Injection show very good resistance to impact and stretching. If you are also curious to know more about the unique features of this material, we suggest you follow this content.

Usage of LLDPE Injection

Due to the low price of LLDPE Injection, this product is used in various fields. But the unique and low price of this chemical is not the only reason for using it to make various products. This material is a very good thermal and electrical insulation. In addition, Liner Low-Density Polyethylene Injection is used for the production of various types of products due to having suitable mechanical properties. In the food industry, this product is used to produce various types of containers and packaging, and disposables. In the packaging industry, this product can be used to produce different types of bottles. Due to its high mechanical, chemical, and thermal resistance, this chemical is suitable for producing different types of packaging bottles. In addition to the issue, in the component manufacturing industry, Liner Low-Density Polyethylene Injection can be used to produce computer parts and various laboratory equipment.

| food industry | used to produce various types of containers and packaging, and disposables |

| packaging industry | used to produce different types of bottles |

| component manufacturing industry | used to produce computer parts and various laboratory equipment. |

Usage of LLDPE Injection

Technical data sheet & chemical Formula

LLDPE Injection, just like other types of polyethylene, is known by the chemical formula (C2H4)n. The unique features of this product are summarized in its versatility and thermal, electrical, and chemical resistance. In addition, the mechanical resistance of this material is one of the factors that have made this chemical be used for the production of various products. Producers can buy Liner Low-Density Polyethylene Injection as a main raw material with the lowest costs and use it in their desired field. This product is highly resistant to humidity and environmental conditions, so as a result, its maintenance and storage do not require high costs.

| Chemical formula | (C2H4)n |

| Density | 0.924 gm/cm3 |

| Melt Flow Index | 50 gm/10min |

| Elongation at Break | 600 % |

| Flexural modulus | 300 Mpa |

How is packing of LLDPE Injection?

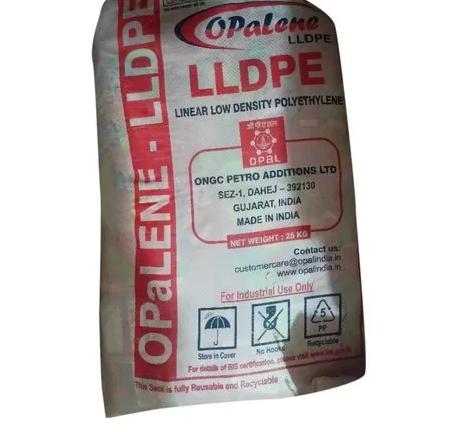

LLDPE Injection is usually produced in granular form. This issue has made the process of selling this product and using it very easy and hassle-free. If you also need Liner Low-Density Polyethylene Injection, you can get the granular form of this model, usually in 25 kg bags. Of course, manufacturers may deliver this product to customers in larger packages. But usually, 25 kg is the contractual weight that almost all manufacturers consider this volume for their products.

How is packing of LLDPE Injection?

Safety & warning & transportation

In general, LLDPE Injection is not so sensitive. In addition, as we told you before, the maintenance of this product does not require special conditions or money. This issue has made you able to get the product you need easily and without any problems and use it. The point that you should pay attention to is that to maintain the quality of the product, it is better to keep it away from sunlight, high heat, and pollution. If you pay attention to these points, the quality of your product can be maintained for a relatively long time. In addition, due to the production of vapors and toxic smells when burning, it is better to use appropriate chemical masks when working with this product.

Reviews

There are no reviews yet.